Power Saving

In today’s economic climate, energy costs are a growing concern for wineries — especially during peak vintage demand. VinWizard’s power-saving tools are designed to reduce energy usage without sacrificing control, consistency, or product quality.

From scheduling and automation to real-time system monitoring and load management, these tools help wineries run leaner, respond faster, and lower utility bills — all with minimal intervention from staff.

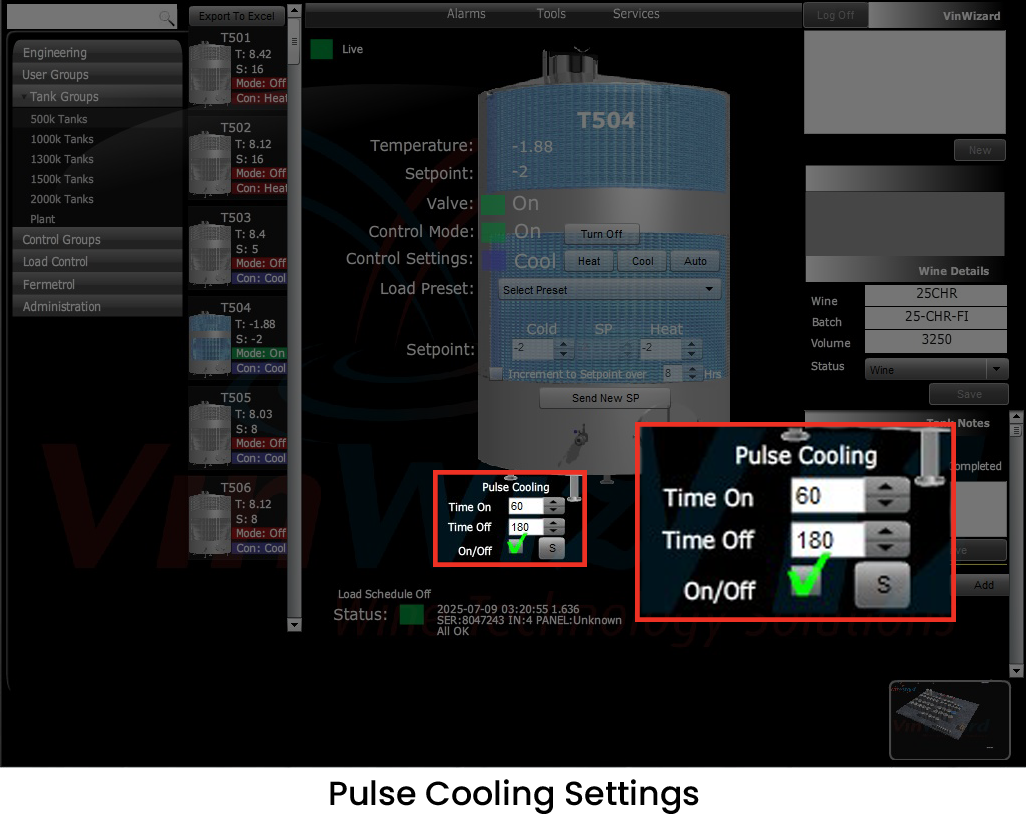

Pulse Cooling

Efficient cooling - without the ice or overkill.

Pulse Cooling replaces the traditional method of continuous coolant flow with a smarter, more efficient cycle. Introduced to VinWizard customers in 2017, this technique delivers coolant to the tank jacket in controlled bursts, then holds it in place to maximize heat transfer — before cycling fresh coolant back in.

Why it works:

Rather than forming a layer of ice (which insulates rather than cools), Pulse Cooling ensures direct contact between the wine and the jacket — making cooling more effective and more energy efficient.

Key Benefits:

No ice build-up inside or outside the tank — improves heat exchange

Warmer glycol returns in bursts to allow chillers to work more efficiently

Stationary coolant transfers heat better than a constant flow

Promotes gentle convection, helping mix the wine naturally

Easier on yeast — avoids the shock of aggressive cooling

Reduces energy demand — fewer tanks call for coolant simultaneously

Higher glycol temps possible, with the same results

Pulse Cooling helps wineries cool with care, not brute force — resulting in better wine and lower energy costs.

Pump Control

Automatic start/stop for glycol & hot water pumps.

VinWizard continuously monitors every tank’s heating and cooling demand. When no tanks are calling, it sends a signal to shut the circulation pumps down; the moment any tank needs heat or cold again, the pumps restart automatically.

Cuts idle energy use — pumps run only when they’re doing useful work

Extends pump life — fewer hours means less wear and maintenance

Quieter cellar floor — reduced vibration and background noise

Simple, reliable automation that saves power and equipment without a single extra click from your team.

Load Scheduling

Automatically adjust tank temperature control based on time of day — helping reduce power consumption without compromising wine quality. Load Scheduling can be applied to individual tanks, tank groups, or driven by the wine status, giving you flexible control and real energy savings.

Scheduled Setpoint Adjustments

Lower your setpoints overnight, then raise them during the day to reduce refrigeration load during peak energy hours. Fine-tune the offset to suit your winery’s needs and local power pricing — all fully automated.

Night Pause

Completely turn off tank cooling at night and resume during the day — ideal for non-critical processes or cooler ambient conditions.

Day Pause

Pause cooling during the day and resume at night to shift energy use away from peak demand hours.

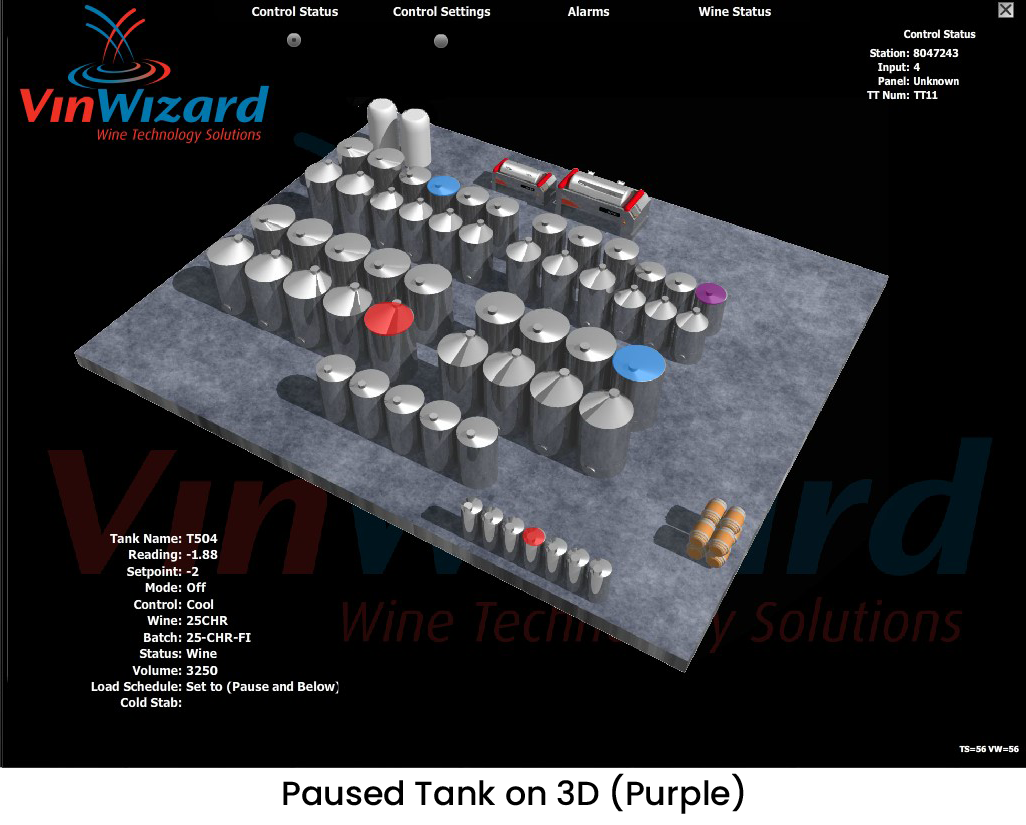

System Temps

Protect your wine from cooling and heating system failures.

The System Temps module continuously monitors the temperatures of your glycol and heating systems to detect supply failures before they impact your wine.

If a failure occurs — for example if the temperature of the glycol is higher than the tank setpoint — the system automatically pauses affected tanks, preventing heat gain or loss that could damage a ferment or stored wine.

Key protections include:

Pauses cooling tanks if glycol temperature is too high

Pauses heating tanks if hot supply is too cool

Automatically resumes normal control once safe temperatures return

No user input required — fully automatic safety feature

This module has prevented major losses at wineries where overnight system failures would have gone unnoticed until morning. System Temps acts as a final safeguard, protecting your wine — and your bottom line.

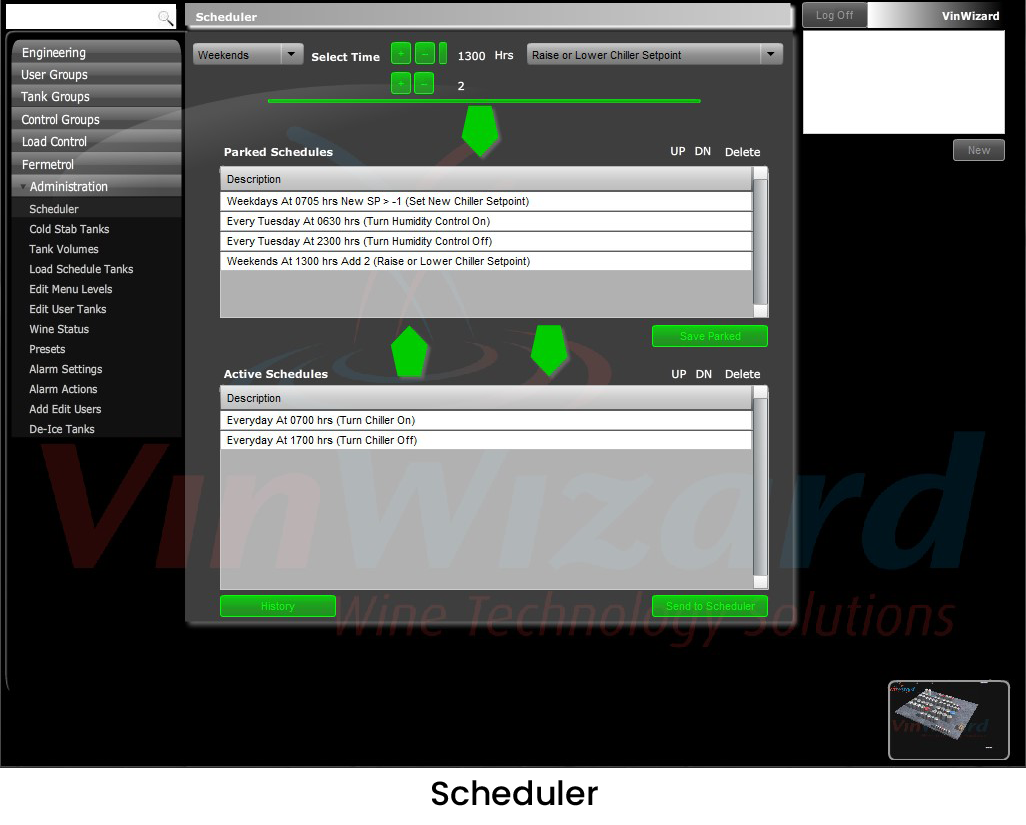

Scheduler

Automated control for winery infrastructure.

The Scheduler module allows you to automate key plant operations beyond tank control — managing equipment like boilers, refrigeration systems, chillers, compressors, and more.

Easily configure run/stop times or setpoint changes for critical systems, based on the day & time. Scheduler integrates with your Custom Mimics, making it possible to manage your entire plant from the VinWizard interface — and ensure everything runs exactly when it should.

Common use cases include:

Turning boilers or chillers on/off automatically

Adjusting chiller setpoints overnight for energy savings

Running ventilation or water systems only during working hours

By putting your plant equipment on a schedule, you reduce manual oversight, cut energy costs, and ensure consistency across shifts — with no extra effort from staff.

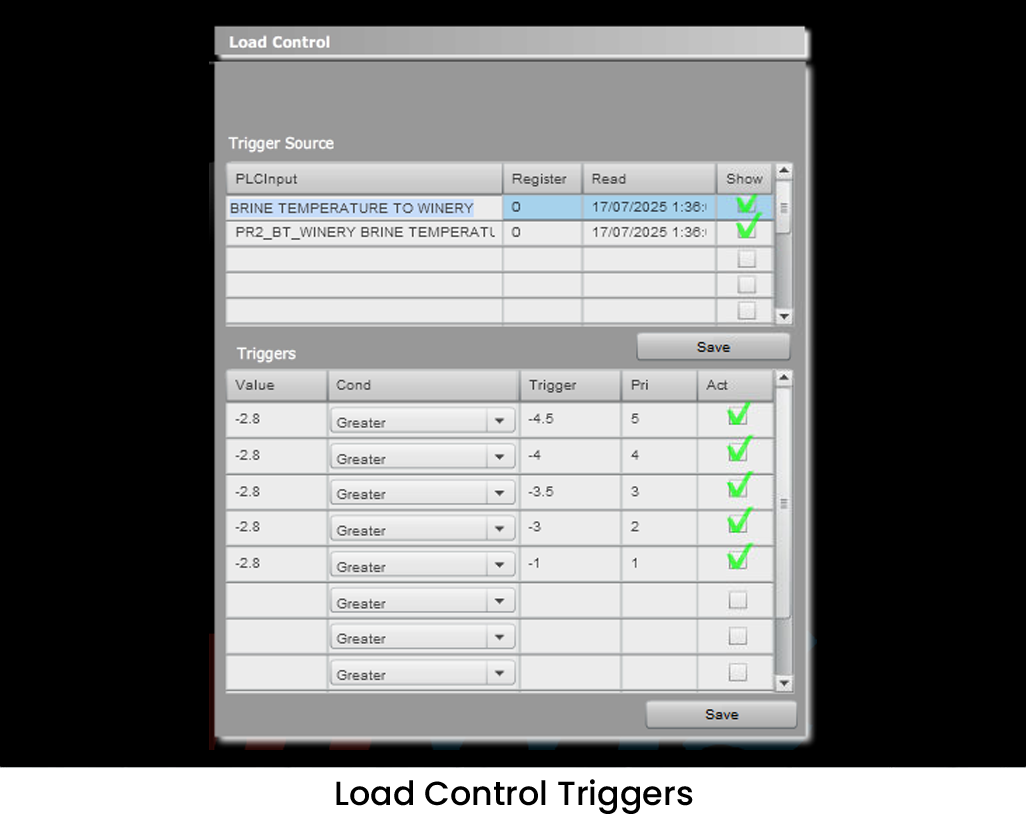

Load Control

Smart load management that protects wine first.

While Load Scheduling helps shift cooling to off-peak hours, Load Control actively monitors system demand in real time and makes dynamic decisions to reduce power or glycol usage — without compromising your wine.

Unlike traditional load shedding (which simply cuts power during high-demand periods), VinWizard’s Load Control prioritizes tanks based on wine status, ensuring critical processes like fermentation stay protected while non-essential loads are temporarily paused.

How it works:

Set a load source trigger — such as glycol temperature, refrigeration load, or maximum power draw.

Assign priority levels to wine statuses (e.g. Ferment = Priority 0, Storage = Priority 1, Settling = Priority 3).

When a trigger is tripped (e.g. glycol too warm or power use too high), lower-priority (Priority 3 in this example) tanks are automatically paused.

Once the system stabilizes, these tanks resume operation — all without staff intervention.

This targeted control ensures your refrigeration plant can keep up with demand, especially during peak times like vintage, while helping avoid utility penalties for exceeding load thresholds.